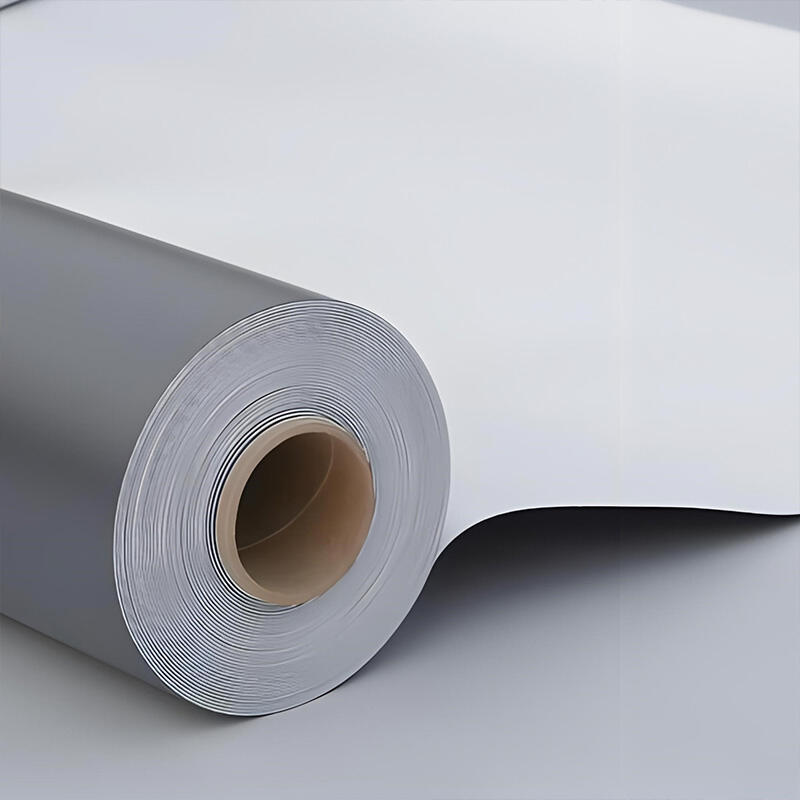

การติดตั้งที่เหมาะสมมีความสำคัญอย่างยิ่งต่อประสิทธิภาพสูงสุดของแผ่นกันซึมน้ำชนิด TPO และที่บริษัท Weifang Luyang Waterproof Materials Co., Ltd. เรามีคำแนะนำและบริการสนับสนุนการติดตั้งแผ่นกันซึม TPO แบบครบวงจร การติดตั้งแผ่นกันซึม TPO โดยทั่วไปจะเริ่มต้นด้วยการเตรียมพื้นผิว พื้นฐานไม่ว่าจะเป็นดาดฟ้า ผนังใต้ดิน หรือพื้นผิวอื่น ๆ จะต้องสะอาด แห้ง และปราศจากเศษวัสดุ ฝุ่น หรือสารปนเปื้อนทุกประเภท เพื่อให้แน่ใจว่าแผ่นกันซึม TPO กับพื้นฐานสามารถยึดติดกันได้อย่างแข็งแรงและเชื่อถือได้ มีหลายวิธีในการติดตั้งแผ่นกันซึม TPO วิธีหนึ่งที่ใช้กันอย่างแพร่หลายคือการเชื่อมด้วยความร้อน โดยใช้เครื่องเป่าลมร้อนเพื่อละลายขอบแผ่นกันซึมจนเกิดการเชื่อมต่ออย่างแนบสนิทและแข็งแรง วิธีนี้ช่วยให้การต่อกันระหว่างแผ่นกันซึมมีความแน่นหนาและลดความเสี่ยงของการรั่วซึมของน้ำได้อย่างมีประสิทธิภาพ อีกวิธีหนึ่งคือการติดตั้งแบบยึดเต็มพื้นที่ โดยการทาสารยึดเกาะบนพื้นผิว จากนั้นวางแผ่นกันซึม TPO ลงบนพื้นผิวอย่างระมัดระวังและกดให้แน่นเพื่อให้ยึดติดได้อย่างสมบูรณ์ วิธีนี้เหมาะสำหรับพื้นผิวเรียบหรือลาดเอียงน้อย และให้การติดตั้งที่มั่นคงและปลอดภัย นอกจากนี้ยังมีวิธีการยึดด้วยอุปกรณ์กลไก เช่น สกรูและแผ่นยึด เพื่อติดตั้งแผ่นกันซึม TPO เข้ากับพื้นฐาน วิธีนี้มักใช้กับหลังคาและโครงสร้างอื่น ๆ ที่ต้องการความแข็งแรงทางกลเพิ่มเติม ทีมงานผู้เชี่ยวชาญของเราจัดทำคู่มือการติดตั้งโดยละเอียดสำหรับแต่ละวิธี ครอบคลุมตั้งแต่การเตรียมวัสดุและเครื่องมือไปจนถึงขั้นตอนการติดตั้งเฉพาะเจาะจง เราพร้อมทั้งให้บริการฝึกอบรมและการสนับสนุนทางเทคนิคในสถานที่จริง เพื่อให้มั่นใจว่าการติดตั้งดำเนินไปอย่างถูกต้อง เมื่อคุณปฏิบัติตามขั้นตอนการติดตั้งของเรา คุณจะสามารถใช้ประโยชน์จากแผ่นกันซึม TPO ของเราได้อย่างเต็มประสิทธิภาพ และยืดอายุการใช้งานให้ยาวนาน สร้างระบบกันซึมที่เชื่อถือได้และทนทาน