Understanding Polymer Membrane Technology and How It Works

What Are Waterproofing Membranes?

Waterproofing membranes serve as these really thin but effective barriers that stop water from getting into buildings. They basically create a shield against moisture, keeping it from damaging important parts of the structure like foundation walls, roof areas, and basement floors. Traditional methods often relied on things like concrete sealants or those old bitumen based coatings, but modern polymer membranes work differently. These new materials blend smart chemical formulations with careful engineering techniques to provide protection that lasts much longer and targets specific problem spots where water tends to seep through.

The Science Behind Polymer-Based Waterproofing Materials

Polymer membranes derive their effectiveness from long-chain molecular structures that form impermeable networks. During application, cross-linking reactions create covalent bonds between polymer chains, enhancing durability and integrity. This molecular architecture enables three critical behaviors:

- Elasticity: Accommodates structural shifts up to 400% elongation in premium formulations

- Chemical stability: Resists degradation from salts, UV radiation, and pH extremes

- Adhesion: Bonds to substrates at up to 350 psi (ASTM D4541)

These properties stem from engineered polymers that maintain performance under mechanical and environmental stress.

Hydrophobic Properties and Long-Term Performance of Polymer Membranes

Polymer membranes get their water-repelling properties mainly from added fluorine or silicone compounds which bring down surface energy levels below around 20 mN/m. This phenomenon is often called the lotus effect since water droplets create contact angles over 110 degrees and simply roll away rather than soaking in. According to accelerated aging tests following ISO 11527 standards, high quality membranes still maintain about 90 percent of their original waterproofing ability even after 25 years of exposure. That durability explains why these materials are growing at an impressive rate of 8.3% per year in commercial roofing applications as reported by Grand View Research back in 2023.

Thermal cycling resistance allows these systems to perform across -40°F to 240°F (-40°C to 116°C), making them ideal for diverse climates from desert heat to Arctic freeze-thaw cycles.

Types of Polymer Membrane Systems in Modern Construction

Modern construction projects rely on five primary polymer membrane systems to address diverse waterproofing needs. Each system offers unique properties tailored to specific structural and environmental demands.

Polyurethane Membrane: Flexibility and Seamless Application

Liquid-applied polyurethane membranes create seamless barriers that conform to complex geometries, making them ideal for curved surfaces and expansion joints. With up to 500% elongation, they accommodate structural movement while maintaining strong adhesion across concrete, metal, and wood substrates.

EPDM Membrane: Synthetic Rubber for Long-Term Durability

Ethylene propylene diene monomer (EPDM) membranes excel in rooftop applications due to inherent ozone and UV resistance. These 1.14–1.5 mm thick sheets withstand temperature fluctuations from -45°C to 130°C without losing elasticity, delivering 30+ year service lives in exposed environments.

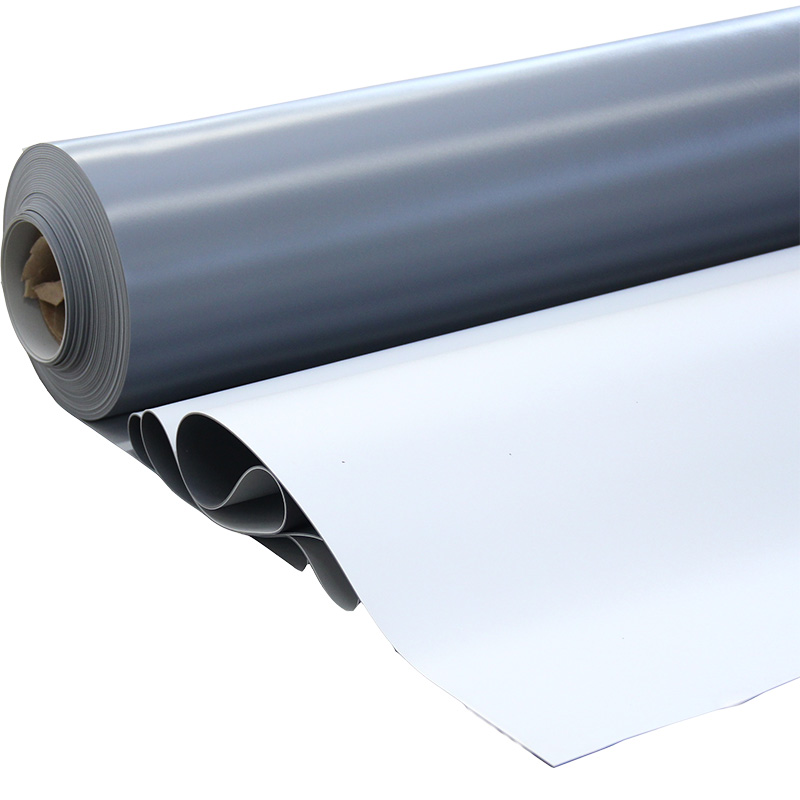

PVC and TPO Membrane: Thermoplastic Solutions for Flat Roofs

Thermoplastic polyolefin (TPO) and polyvinyl chloride (PVC) sheets provide puncture-resistant solutions for flat commercial roofs. Welded seams create monolithic surfaces that reflect 85% of solar radiation, reducing urban heat island effects while resisting chemical exposure from airborne pollutants.

Polymer-Modified Bitumen: Hybrid Performance in Extreme Climates

Bitumen membranes reinforced with styrene-butadiene-styrene (SBS) polymers combine traditional asphalt waterproofing with modern flexibility. These torch-applied systems remain functional at -25°C and resist hail impact up to 50 mm in diameter, outperforming conventional asphalt in freeze-thaw cycling tests.

Comparative Advantages: Synthetic Rubber vs. Thermoplastic Polymer Membranes

| Property | Synthetic Rubber (EPDM) | Thermoplastic (PVC/TPO) |

|---|---|---|

| Installation Temperature | -18°C to 50°C | 4°C to 40°C |

| Seam Strength | Adhesive-bonded (15N/mm²) | Heat-welded (35N/mm²) |

| Thermal Movement | 1.5% linear expansion | 2.2% linear expansion |

| Recyclability | Limited (30% reuse) | Fully recyclable |

| Lifecycle Cost | $0.22/sf/year | $0.18/sf/year |

Synthetic rubber membranes offer superior cold-weather performance, while thermoplastic systems provide higher seam integrity and environmental benefits. Recent material advances have narrowed the performance gap, with hybrid membranes now achieving 60% longer fatigue resistance than 2019 benchmarks.

Application Forms: Liquid, Sheet, Caulk, and Gel Polymer Membranes

Modern construction demands polymer membrane solutions tailored to structural complexity and environmental exposure. Below, we break down the four primary application forms and their unique advantages.

Liquid-Applied Polymer Membranes: Seamless and Custom-Fit Protection

When liquid polymer membranes cure, they form flexible rubber-like layers that fit around all sorts of uneven surfaces. This means no more seams, which are basically where most traditional systems fail. These materials stick right onto things like concrete walls or metal structures too. Tests show they let through less than 1 percent water vapor even after being aged quickly in lab conditions. And what about flexibility? Some polyurethane versions can stretch up to three times their original length before breaking. That kind of give lets them handle building movements over time while still keeping everything watertight underneath.

Sheet Membranes: Prefabricated Reliability for Large Surfaces

Prefabricated polymer sheets offer instant coverage for roofs, foundations, and plaza decks. High-tensile EPDM and PVC variants withstand puncture forces exceeding 200 N/mm², making them ideal for rapid deployment. Unlike liquid systems, sheets provide consistent thickness (1–3 mm) without curing delays, though complex geometries may require supplementary sealing.

Caulks and Gels: Precision Sealing for Joints and Cracks

Hybrid polymer gels combine silicone’s elasticity (<50% compression set) with polyurethane’s adhesion strength (≥500 psi). These cartridged materials seal expansion joints and pipe penetrations where bulk membranes fall short. Advanced formulations self-level in gaps as narrow as 0.5 mm while resisting mold growth in 95% RH environments.

Choosing the Right Form Based on Project Requirements

| Factor | Liquid | Sheet | Caulk/Gel |

|---|---|---|---|

| Application Speed | Moderate | Fast | Fast |

| Complex Geometry | Excellent | Poor | Good |

| Longevity (Years) | 25–50 | 20–40 | 15–30 |

| Cost per m² (USD) | $18–35 | $12–25 | $40–75 |

Prioritize liquid systems for curved façades, sheet membranes for flat roofs, and gels for dynamic joints. Multi-form strategies—like pairing sheet membranes with perimeter sealants—prevent 92% of warranty claims related to water ingress (Building Envelope Council 2023).

Durability, Adhesion, and Resistance to Structural Movement

Polymer membranes hold up pretty well when stressed, with certain types stretching as much as 300% before breaking, which helps buildings move without developing cracks. These materials stick firmly to surfaces such as concrete and steel, forming bonds that stop water from getting through even when there's earth movement or settling happening beneath the surface. What makes them stand out is their ability to withstand damage from harsh chemicals typically present in city settings salt, acid rain, and alkaline substances. This resistance means they can last for many years without needing replacement, making them a smart choice for long term waterproofing solutions in construction projects across different climates.

Performance Across Climates: From Arid to Coastal Environments

The membranes work well across a pretty wide temperature range, from as low as minus 40 degrees Fahrenheit all the way up to 200 degrees Fahrenheit (that's about minus 40 Celsius to 93 Celsius). When installed in dry areas where the sun beats down constantly, these membranes contain special UV stabilized polymers that stop them from getting brittle after months of direct sunlight. Around coastal areas too, manufacturers have developed salt resistant versions specifically for this environment since regular materials tend to corrode pretty quickly there. And let's not forget about colder regions either. Some membranes can actually handle over 150 freeze thaw cycles without losing their flexibility, which gives them a real edge compared to old fashioned asphalt systems that crack and break down much faster when faced with extreme weather conditions.

Lifecycle Cost Analysis: Initial Investment vs. Long-Term Savings

Polymer membranes might set businesses back around 20 to 30 percent more initially when compared to standard bitumen sheets, but what they lack in upfront price they make up for over time. These materials typically last well beyond half a century, which means replacing them happens roughly four times less frequently than traditional options. When it comes to maintenance expenses, building owners report seeing reductions between 40 and 60 percent across twenty years because there are simply not as many problems with leaks or needed repairs. According to research published in 2023 about roofing solutions, facilities that switched to polymer membranes ended up saving approximately seven dollars fifty cents per square foot throughout the entire life cycle of the roof. To put this into real world terms, that adds up to nearly $190k saved on just a quarter acre sized commercial property.

Innovations and Future Trends in Smart and Sustainable Polymer Membranes

Self-Healing Polymers and Nanotechnology Integration

Self-healing polymer membranes autonomously repair micro-cracks through embedded agents that react to moisture or stress. Nanotechnology enhances performance with additives like graphene oxide, improving tensile strength by up to 40% while preserving flexibility. This innovation reduces maintenance and extends service life, especially in high-stress areas like foundation walls and rooftops.

Eco-Friendly Formulations: Recyclable and Low-VOC Polymer Membranes

Manufacturers are advancing sustainability through recyclable thermoset polymers and low-VOC formulations. Breakthroughs in covalent adaptable networks now enable end-of-life recycling—supporting circular construction practices. Modified polyurethane membranes, for example, achieve 85% recycled content without sacrificing adhesion or hydrolytic stability, as highlighted in recent sustainable materials research.

Digital Integration: BIM and Predictive Maintenance in Waterproofing Design

The integration of polymer membrane performance data into Building Information Modeling (BIM) platforms helps designers get better at setting installation tolerances and figuring out proper drainage slopes. Membranes equipped with IoT technology and built-in sensors now give instant warnings about leaks and can actually forecast when materials might start breaking down through machine learning algorithms. This kind of early warning system catches problems long before they become serious failures. What does all this mean for building owners? Studies show that these digital advancements cut down on costly waterproofing repairs by around 60 percent throughout the life of a structure, making a real difference in maintenance budgets.

Frequently Asked Questions (FAQ)

What are the main types of polymer membrane systems used in construction?

There are five main types: Polyurethane, EPDM, PVC/TPO, Polymer-Modified Bitumen, and Synthetic Rubber membranes. Each has its own benefits tailored to different construction needs.

How do polymer membranes contribute to sustainability?

Polymer membranes are advancing in sustainability through recyclable thermoset polymers and low-VOC formulations. Some types can contain up to 85% recycled content without losing performance.

What are the advantages of self-healing polymers?

Self-healing polymers can autonomously repair micro-cracks, which reduces maintenance needs and extends the service life of the membrane, proving valuable in high-stress areas.

How do polymer membranes perform across different climates?

They are highly versatile, performing well in a wide temperature range from -40°F to 200°F and handling freeze-thaw cycles well, making them suitable for both arid and coastal environments.

What is the lifecycle cost benefit of using polymer membranes?

Although more expensive upfront, polymer membranes can lead to significant long-term savings due to their durability and low maintenance needs. They can last over half a century, reducing the frequency of replacements.

Table of Contents

- Understanding Polymer Membrane Technology and How It Works

-

Types of Polymer Membrane Systems in Modern Construction

- Polyurethane Membrane: Flexibility and Seamless Application

- EPDM Membrane: Synthetic Rubber for Long-Term Durability

- PVC and TPO Membrane: Thermoplastic Solutions for Flat Roofs

- Polymer-Modified Bitumen: Hybrid Performance in Extreme Climates

- Comparative Advantages: Synthetic Rubber vs. Thermoplastic Polymer Membranes

- Application Forms: Liquid, Sheet, Caulk, and Gel Polymer Membranes

- Durability, Adhesion, and Resistance to Structural Movement

- Performance Across Climates: From Arid to Coastal Environments

- Lifecycle Cost Analysis: Initial Investment vs. Long-Term Savings

- Innovations and Future Trends in Smart and Sustainable Polymer Membranes

-

Frequently Asked Questions (FAQ)

- What are the main types of polymer membrane systems used in construction?

- How do polymer membranes contribute to sustainability?

- What are the advantages of self-healing polymers?

- How do polymer membranes perform across different climates?

- What is the lifecycle cost benefit of using polymer membranes?