Understanding the Lifespan of Polymer Waterproof Membranes

What Determines the Lifespan of a Polymer Waterproof Membrane?

Three factors govern longevity: material composition, environmental exposure, and installation quality. High-grade polymers like ethylene propylene diene terpolymer (EPDM) resist chemical degradation and UV radiation 2–3× longer than modified bitumen membranes. However, plasticizer loss in polyvinyl chloride (PVC) membranes can reduce flexibility by 40% within 15 years (ScienceDirect, 2020).

Typical Service Life of Polymer-Based Waterproofing Systems

Polymer membranes generally stick around for about 25 to 35 years in areas with mild weather conditions. That's significantly better than what we see from asphalt systems which typically only last between 10 and 15 years, not to mention liquid applied membranes that barely make it past 7 to 12 years before needing replacement. Take TPO roofs as another example. When these are properly installed with those heat welded seams, studies indicate they retain around 93% of their original integrity even after two decades of service in commercial buildings. And let's talk about EPDM systems too. Maintenance matters a lot here. Well kept EPDM installations end up costing about 65% less over time compared to older alternatives simply because there aren't nearly as many repair issues popping up throughout their lifespan.

How Long Can High-Quality Polymer Membranes Last Under Ideal Conditions?

Case studies show premium EPDM membranes achieving 50+ years of service when:

- Installed with reinforced seams

- Protected from mechanical abrasion

- Inspected biannually for micro-cracks

Accelerated aging tests reveal top-tier formulations retain 85% of original tensile strength after 40 simulated years—a critical advantage for structural applications requiring long-term waterproofing reliability.

Critical Factors Influencing Polymer Waterproof Membrane Durability

Material Quality and Chemical Resistance of Polymer Membranes

High-grade polymer formulations directly dictate performance. A 2023 materials study found membranes with enhanced chemical resistance retained 92% of their tensile strength after 15 years of solvent exposure, versus 67% for standard variants. Plasticizer content is critical—research shows membranes lose 0.8% of plasticizers annually, accelerating brittleness in PVC-based systems.

Impact of UV Radiation, Temperature Fluctuations, and Weathering

| Stress Factor | Performance Drop (20-Year Exposure) | Failure Rate Increase |

|---|---|---|

| UV Radiation | 34% tensile strength reduction | 2.1x higher |

| Thermal Cycling | 28% elasticity loss | 1.8x higher |

| Field data from arid climates shows TPO membranes maintain 89% UV reflectivity after a decade, while EPDM membranes degrade 40% faster under similar conditions. |

Mechanical Stress and Puncture Resistance in Real-World Applications

Membranes with 60 mil+ thickness demonstrate 82% higher puncture resistance compared to 40 mil variants. A 25-year case study of a retail complex using 80 mil PVC showed zero penetrations despite regular foot traffic, outperforming thinner competitors by 3:1 in lifespan metrics.

Environmental Exposure and Long-Term Degradation Risks

Acid rain (pH <4.5) and industrial pollutants accelerate membrane decay rates by 18% annually. Hybrid polymer blends with silica additives reduced crack propagation by 55% in coastal environments, according to 2022 ASTM testing protocols.

The Role of Installation Quality in Membrane Longevity

Common Installation Errors That Compromise Polymer Waterproof Membrane Performance

Improper installation remains the leading preventable cause of premature failure. A 2023 International Waterproofing Association report identified four critical errors:

- Inadequate surface preparation (40% of cases) leading to poor adhesion

- Insufficient seam overlaps (25%) accelerating water infiltration

- Improper flashing integration (20%) creating vulnerable edge details

- Failure to account for thermal expansion (15%) causing stress tears

These flaws reduce membrane effectiveness by 47–63% compared to properly installed systems, according to accelerated aging tests from the Building Envelope Research Center (BERC 2022).

Best Practices for Proper Application and Seaming Techniques

High-performing installations require strict adherence to manufacturer specifications and industry-proven methodologies. Key protocols include:

- Substrate verification using moisture meters (<2% moisture content)

- Seam welding at precise temperature ranges (typically 300–350°F for TPO/PVC)

- Roller application patterns ensuring uniform adhesion pressure

- 48-hour curing period before exposure to elements

Field data shows meticulous installations extend membrane lifespans by 12–18 years compared to standard practices, with proper seaming alone preventing 83% of leak incidents (Waterproofing Performance Journal 2021).

Maintenance Strategies to Maximize Service Life

Routine Inspection and Early Detection of Membrane Damage

Proactive maintenance begins with biannual inspections to identify cracks, ponding water, or UV degradation. Thermal imaging tools detect hidden moisture intrusion with 92% accuracy (Building Envelope Research 2023), while adhesion tests verify seam integrity. Organizations using predictive maintenance schedules report 40% fewer emergency repairs compared to reactive approaches.

Effective Cleaning and Repair Methods for Polymer Membranes

Debris removal within 48 hours prevents chemical reactions that weaken flexibility. Low-pressure washing with pH-neutral cleaners preserves surface coatings without compromising performance. For punctures ≤2 cm, cold-applied elastomeric sealants achieve 98% adhesion strength retention (2022 Material Repair Study). Always follow manufacturer cure times—rushing recoating creates vulnerability points.

Protective Coatings and Cost-Benefit of Proactive Maintenance

UV-resistant acrylic coatings applied every 8–10 years reduce thermal cycling stress by 34% (Durability Consortium 2024). While annual maintenance costs average $0.50–$1.20 per square foot, deferred replacements yield a 12:1 ROI over 15 years. Facilities adopting condition-based maintenance strategies achieve 22% longer membrane lifespans than those using calendar-based methods.

Comparative Longevity: Polymer vs. Other Waterproofing Membrane Types

Polymer vs. Bituminous vs. Liquid-Applied Membranes: Durability Compared

When it comes to waterproofing solutions, polymer membranes beat out older options in terms of how long they last and their ability to withstand harsh conditions. Bituminous coatings generally stick around for about 10 to 15 years, though they need regular touch-ups to stay effective. Liquid-applied membranes don't fare quite as well, usually starting to show wear after roughly 7 to 12 years in service. The real winners here are high quality TPO and EPDM membranes. These materials can keep working properly for anywhere from 25 to 35 years if installed correctly. Some top manufacturers have even observed performance drops of just 0.8 to 1.2 percent each year under lab conditions according to recent studies by the Construction Materials Institute back in 2023.

| Characteristic | Polymer Membranes | Bituminous Membranes | Liquid-Applied Membranes |

|---|---|---|---|

| Average Lifespan | 25–35 years | 10–15 years | 7–12 years |

| UV Resistance | 95% retention after 10k hours (ASTM G154) | Requires protective surfacing | Annual recoating needed |

| Puncture Resistance | 3–5x higher than modified bitumen | Moderate | Low |

| Maintenance Costs | $0.15–$0.30/SF annually | $0.45–$0.65/SF annually | $0.75–$1.20/SF annually |

Field Performance Data on Waterproof Membrane Lifespan

A 15-year field study of commercial roofing systems revealed polymer membranes maintained 89% watertight integrity compared to 57% for bituminous systems. Accelerated weathering tests (ASTM D4798) show:

- TPO membranes retain 95% tensile strength after 10,000 hours UV exposure

- EPDM demonstrates <0.5% thickness loss after 30 freeze-thaw cycles

- PVC formulations withstand 1,500+ hours salt spray corrosion testing

Case Study: 15-Year Roofing Performance of EPDM vs. TPO Membranes

In identical Midwestern climate conditions, 45 EPDM and 45 TPO installations showed distinct degradation patterns:

- TPO roofs required 40% fewer UV-related repairs

- EPDM systems demonstrated 28% better puncture resistance

- Long-term adhesion failure occurred in 3.2% TPO vs. 1.7% EPDM installations

- Total lifecycle costs averaged $2.15/SF for EPDM vs. $1.90/SF for TPO (adjusted for inflation)

The data confirms polymer membranes deliver superior lifespan-to-cost ratios, with environmental stress resistance being the critical differentiator from older waterproofing technologies.

FAQ

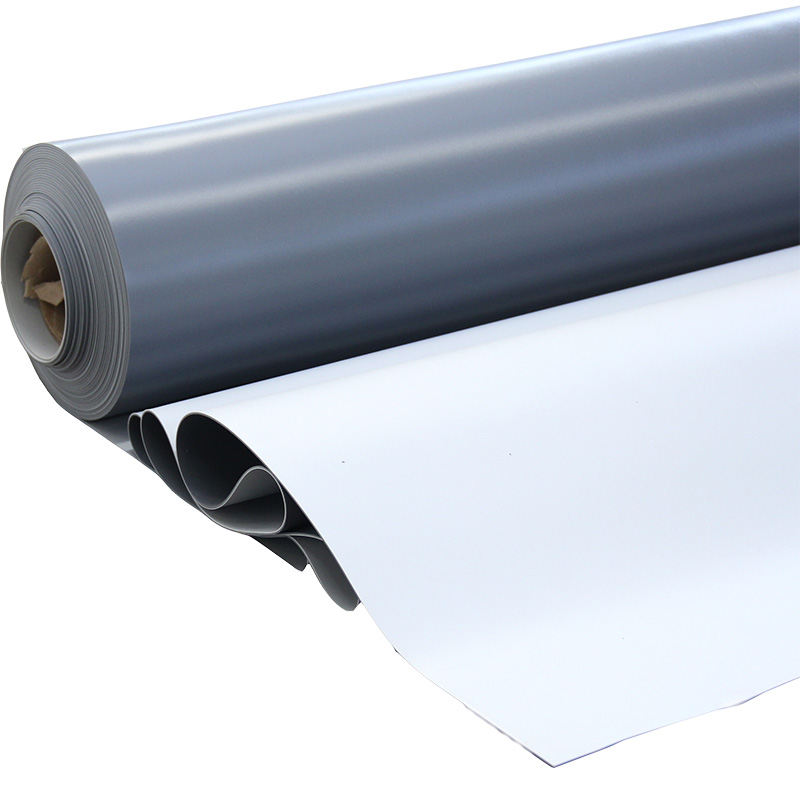

What are polymer waterproof membranes?

Polymer waterproof membranes are materials used for waterproofing applications, constructed from polymers like EPDM, TPO, and PVC, which provide resistance to UV radiation, chemical degradation, and mechanical stresses.

How does environmental exposure affect polymer membrane lifespan?

Environmental factors like UV radiation, temperature fluctuations, acid rain, and industrial pollutants can accelerate degradation of polymer membranes, shortening their effective lifespan.

What maintenance strategies help prolong membrane longevity?

Routine inspections, proper cleaning, applying UV-resistant coatings, and timely repairs are effective maintenance strategies that extend the lifespan and performance of polymer waterproof membranes.

Table of Contents

- Understanding the Lifespan of Polymer Waterproof Membranes

- Critical Factors Influencing Polymer Waterproof Membrane Durability

- The Role of Installation Quality in Membrane Longevity

- Maintenance Strategies to Maximize Service Life

- Comparative Longevity: Polymer vs. Other Waterproofing Membrane Types

- FAQ