What Is a Damp Proof Course Waterproof Membrane and How Does It Work?

Definition and Core Function of a Damp Proof Course Waterproof Membrane

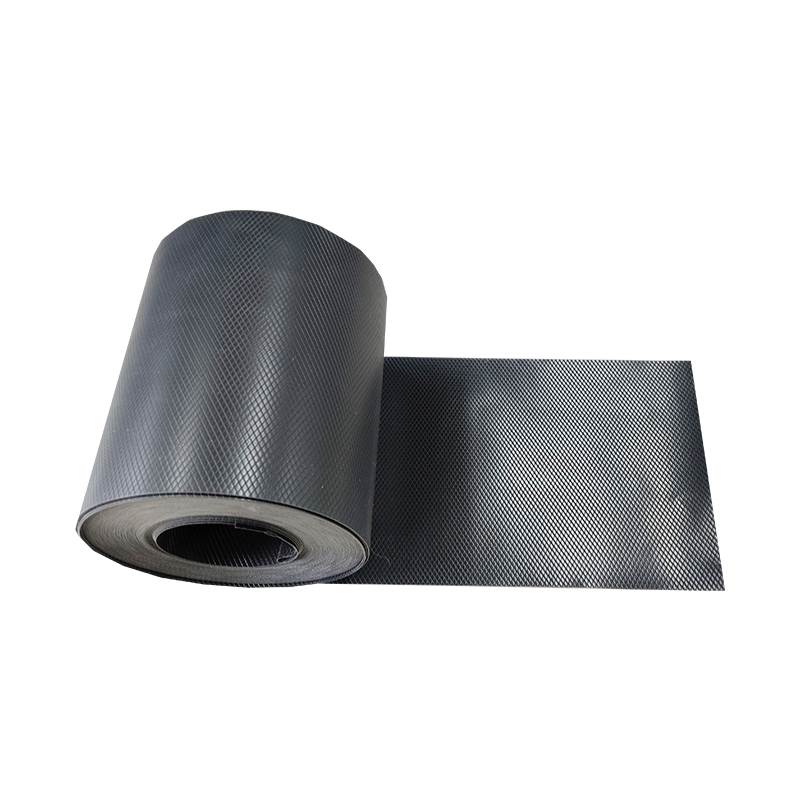

Damp proof course membranes act as barriers within buildings to stop moisture from moving both up and across surfaces. They basically stop groundwater, rainwater, and general humidity from getting into walls, floors, and foundation areas where it can cause problems for the structure itself and affect indoor air quality too. What makes these membranes effective is their ability to resist water pressure pushing against them, yet still allow for small movements in the building caused by things like temperature fluctuations or when the ground settles over time.

The Role of Capillary Action in Rising Damp and How Membranes Block It

When groundwater climbs upward through bricks or concrete walls, it causes rising damp. This happens because of something called capillary action where water somehow manages to move upwards through tiny spaces between particles. To stop this problem, modern damp proof courses act as barriers either physically or chemically blocking the path. These are generally placed around 150 to maybe even 200 millimeters above floor level depending on local conditions. Some newer versions have special micro pores that let water vapor escape but keep liquid water out. This clever design breaks the continuous path water would normally take through walls without getting them soaked from trapped moisture inside.

Material Composition of Modern Damp Proof Course Waterproof Membranes

Today’s membranes are engineered for durability and adaptability:

- Bituminous blends: Modified with polymers like APP or SBS for flexibility across temperatures (-20°C to 100°C)

- High-density polyethylene (HDPE): Provides over 98% water resistance with tear strengths exceeding 500 N/mm²

- Elastomeric hybrids: Combine rubber polymers with reinforcing fabrics to bridge cracks up to 5 mm

Integration with Building Structures for Optimal Moisture Resistance

Effective installation ensures seamless integration with key structural elements:

- Below-grade applications: Lapped and welded to foundation waterproofing systems

- Wall junctions: Extended 100–150 mm beyond vulnerable areas such as window sills

- Service penetrations: Sealed using compatible elastomeric collars to maintain continuity

By aligning with a building’s thermal and structural dynamics, these membranes deliver comprehensive moisture management without compromising energy efficiency or architectural design.

Types of Damp Proof Course Waterproof Membranes and Their Ideal Applications

Bituminous Membranes: Reliability in Traditional Construction

Bituminous damp proof course membranes have become go-to solutions for restoring old buildings and working with heavy masonry structures. These materials come in various forms including asphalt soaked felt sheets or fiberglass reinforced bitumen layers. What makes them stand out is their ability to stop water from creeping up through tiny cracks while still allowing for minor shifts in building structures over time. Most contractors swear by these membranes for underground work such as foundation walls and basement floors. According to field reports from construction experts, around 85 percent of installations keep moisture at bay for twenty years or more provided the seams between sections are properly overlapped during installation. This kind of durability explains why so many preservationists continue relying on bituminous membranes despite newer alternatives entering the market.

PVC and Polyethylene-Based Sheet Membranes in Modern Builds

In modern commercial buildings, PVC and polyethylene sheets have become go to options because they resist chemicals and install pretty easily. These materials are light weight and can handle some serious temperature swings from about minus 30 degrees Celsius all the way up to 80 degrees without breaking down. They work great on those flat roof areas and especially on green roofs where plants grow. Recent tests back in 2024 showed something interesting too. The PVC stuff kept working as a water barrier at around 92 percent effectiveness even after sitting out there for fifteen whole years near the coast. That kind of performance makes these membranes perfect choices when building needs to withstand harsh weather conditions over time.

Liquid-Applied vs. Sheet-Based Damp Proof Course Waterproof Membranes

| Factor | Liquid-Applied Membranes | Sheet Membranes |

|---|---|---|

| Installation Speed | 2–3 hours curing time per layer | Immediate coverage |

| Complex Geometries | Conforms to irregular surfaces | Requires precise cutting |

| Long-Term Maintenance | Easier spot repairs | Full-section replacement |

Liquid-applied systems (e.g., polyurethane, epoxy) are preferred for retrofits with complex details, while sheet membranes provide rapid, reliable protection for large, flat surfaces such as podium decks.

Selecting the Right Membrane Based on Climate and Structural Needs

In freeze-thaw regions, elastomeric membranes with ʻ300% elongation ensure resilience under cyclic stress. For seismic zones, pair polyethylene sheets with flexible sealants at joints to maintain continuity during movement. Always verify compliance with local regulations—for example, BS 8102 requires a minimum 1.5mm thickness for below-ground membranes in UK flood-prone areas.

Best Practices for Installing Damp Proof Course Waterproof Membrane Systems

Surface Preparation and Substrate Requirements

Getting good results starts with proper prep work on the substrate. The surface needs to be spotless, completely dry, and shouldn't have any bumps or rough spots bigger than about 3 millimeters since these will mess up how things stick together and might let water sneak through later. Most contractors use mechanical grinding or wire brushes first, then suck up all the dust with a vacuum cleaner to get that solid foundation right. Industry stats show something pretty shocking actually – around 8 out of 10 membrane failures happen because someone didn't take enough time cleaning the surface properly before starting. Before applying anything, check that the material underneath isn't holding too much moisture. A quick carbide test should tell us if the moisture level is under 4%, which is important for making sure everything bonds correctly in the long run.

Sealing Joints, Corners, and Penetrations Effectively

Around two thirds of all basement water problems actually start at joints, corners, and where pipes pass through walls according to BS 8102 from 2022. These weak spots need special attention. Contractors usually reinforce them with those pre-made corner pieces or stick on some self adhesive flashing tape, making sure the overlaps are about 15 centimeters long. For PVC membranes, heating them works best while bituminous systems respond well to solvent based glues. Keep pressing down firmly while everything sets up properly. Interesting research shows that when seams are staggered instead of lined up straight across, water tends to move sideways less. Some tests indicate this can cut lateral movement by around 40%, which makes a big difference in how well the whole waterproofing system holds together over time.

Avoiding Common Installation Mistakes That Compromise Performance

Some common mistakes happen when people stretch membranes too far. This actually makes the material less dense and speeds up how quickly it breaks down from UV exposure. Another problem comes from not giving enough time for liquid applied systems to cure properly, which leads to cracks forming much sooner than expected. And let's not forget about drainage either. If there's no good drainage system in place, water builds up behind the membrane creating hydrostatic pressure that increases chances of complete system failure. Most building specs these days suggest combining membranes with perimeter drains that slope around 2 percent downward. These channels help move away groundwater before it becomes a bigger issue down the road.

Quality Assurance During and After Installation

After installation, conduct a 48-hour flood test to detect leaks indicated by bubbles or discoloration. Infrared thermography identifies hidden voids with 95% accuracy, enabling non-destructive verification of membrane continuity. Document all inspections against ISO 9001:2015 standards to support compliance claims and warranty validation.

Evaluating Long-Term Performance and Industry Standards

Durability, Aging Resistance, and Lifespan of Waterproof Membranes

Modern damp proof course membranes can stick around for over 25 years if they're properly chosen and put in place right from the start. How long they actually last really comes down to how well they stand up against things like repeated freezing and thawing, salt from sea air, and sunlight damage. Some tests done along coastlines have shown that polyethylene membranes still block water at around 98% efficiency even after 15 years sitting there. That's pretty impressive compared to traditional bitumen products which only manage about 85% effectiveness by then. These results match what we see in industry standards like ISO 9088, so it makes sense why builders are increasingly picking materials based on what kind of weather conditions their buildings will face day in and day out.

Water Permeability Testing and Compliance with BS 8102 and Other Standards

The BS 8102:2022 standard demands pretty tough water permeability standards actually requiring membranes to hold against 1.5 bar hydrostatic pressure over a full 72 hour period without showing any leaks at all. Meeting this benchmark makes a system eligible for Type A tanked waterproofing solutions specifically designed for underground construction projects. Independent certification bodies like the BBA Agrément give their stamp of approval after running accelerated aging tests that mimic what materials would experience over roughly three decades in service. Looking at how these systems perform involves checking several key areas including how well joints stay intact under stress, their ability to resist chemicals they might encounter, and most importantly whether they can handle whatever Mother Nature throws at them in actual installation conditions.

Real-World Case Study: Membrane Performance in Coastal, High-Humidity Zones

Research over seven years looking at homes along the coast showed something pretty interesting about PVC membranes. They cut down on repairs related to damp by around 62% when compared with old school methods. Now here's what happens in areas where there's lots of salt in the air (think 5,000 mg per cubic meter or more). If these installations weren't up to standard, they would start corroding pretty quickly. But those systems that followed BS 8102 standards kept moisture moving through them at less than half a percent. So what does this mean? Well, it really drives home how important it is to pick the right materials based on where they'll be installed and make sure whoever does the job knows what they're doing. Get this wrong and all that money spent could go down the drain.

Innovations Shaping the Future of Damp Proof Course Waterproof Membranes

Smart Membranes with Embedded Moisture-Sensing Technology

The latest membranes on the market come equipped with these fancy IoT sensors that keep track of moisture levels all day long. What makes them so useful is that they actually warn building staff about possible leaks way before anyone would notice any actual water damage happening somewhere. This feature really shines in places where flooding is common or spots that are just plain difficult to check regularly. If connected properly to existing building systems, these membranes will automatically kick off drainage mechanisms whenever humidity gets too high for comfort. According to various industry reports floating around lately, facilities implementing this kind of early warning system tend to save around 30 something percent on those expensive repair bills down the road.

Sustainable and Eco-Friendly Materials in Waterproofing

Many manufacturers are now turning to bio-based resins along with recycled polyethylene as they try to keep up with stricter environmental regulations. Research published in 2023 found that membranes created using plant based materials actually reduce carbon emissions by around 62 percent when compared against traditional bitumen based alternatives. What makes this even better is that these new materials still pass the 100 hour water resistance test specified in ASTM D779 standards. Another important factor worth noting is that approximately 85% of these green components can either be recycled or put to other uses once their useful life ends. This helps move things closer to what we call a circular economy where waste gets minimized rather than simply moved somewhere else.

Integration with BIM for Precision in Design and Maintenance

Building Information Modeling or BIM allows for extremely precise planning when it comes to where membranes should go before construction even starts. Contractors working on these projects rely heavily on those 3D models to spot areas where water might get in and figure out how best to arrange overlaps at different joints. This approach cuts down on wasted materials and makes work on site much smoother overall. After everything gets installed, the data collected through BIM continues to be valuable for maintenance purposes too. By keeping track of how things age over time, teams can schedule repairs and replacements right when they need them, based on actual performance data rather than guesswork.

Self-Healing Membranes: The Next Frontier in Damp Proofing

Self healing membranes on the market now actually have tiny polymer capsules inside them that spring into action when they touch water, fixing cracks as big as half a millimeter across. Field tests along coastlines show these membranes stay almost completely waterproof for fifteen whole years, which beats regular membranes by about forty percent. Factories located in places where humidity is always through the roof have started using them too. Some plant managers say their emergency repair calls dropped by nearly ninety percent since switching, so maintenance budgets aren't getting eaten away quite so fast anymore. The long term money saved plus fewer breakdowns makes these membranes worth considering despite the higher upfront cost.

FAQ

What is a damp proof course waterproof membrane?

A damp proof course waterproof membrane is a barrier installed within buildings to prevent moisture from seeping up and across surfaces, effectively stopping groundwater, rainwater, and humidity from penetrating walls, floors, and foundations.

What materials are used in damp proof course waterproof membranes?

Modern damp proof course membranes are made from materials like bituminous blends, high-density polyethylene, and elastomeric hybrids, engineered for flexibility, water resistance, and durability.

Why is proper installation important for these membranes?

Proper installation is crucial to ensure the membrane fully integrates with the building structure, providing effective moisture management without compromising energy efficiency or design.

What are common mistakes when installing waterproof membranes?

Common mistakes include improper surface preparation, stretching membranes too far, insufficient curing times for liquid-applied systems, and neglecting drainage solutions.

Table of Contents

- What Is a Damp Proof Course Waterproof Membrane and How Does It Work?

- Types of Damp Proof Course Waterproof Membranes and Their Ideal Applications

- Best Practices for Installing Damp Proof Course Waterproof Membrane Systems

- Evaluating Long-Term Performance and Industry Standards

- Innovations Shaping the Future of Damp Proof Course Waterproof Membranes

- FAQ