What Determines the Durability of PVC Membrane Systems?

Defining Durability: Key Performance Metrics for PVC Membranes

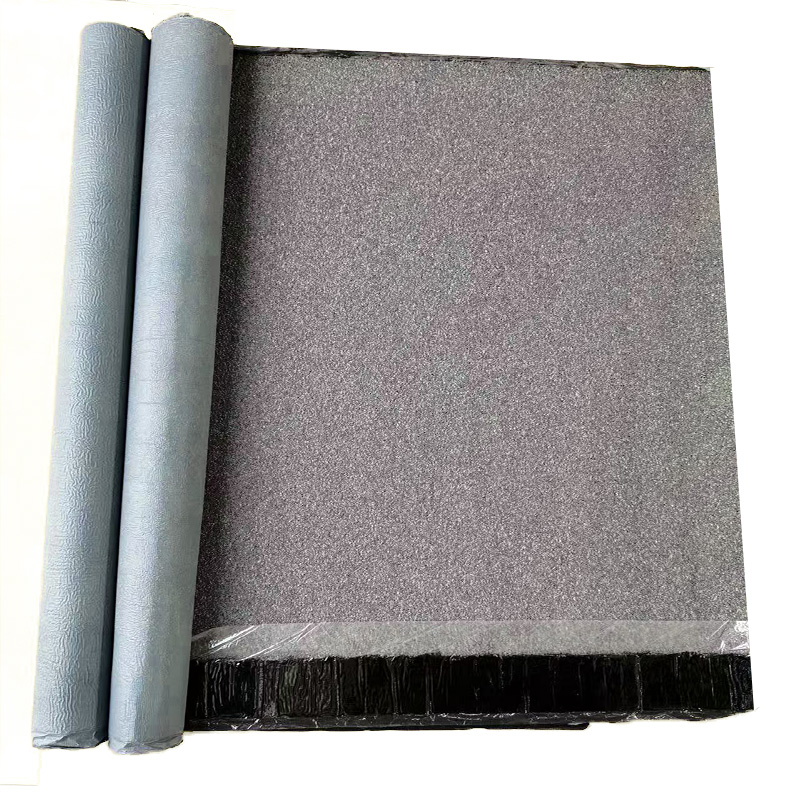

The durability of PVC membranes really comes down to three main factors: how well they stand up to environmental conditions, their mechanical strength when stressed, and their ability to maintain chemical stability over time. When looking at performance, important measures are things like tensile strength, which can hit around 300 psi or more in reinforced versions, puncture resistance, and the retention of plasticizers that keep the material flexible in the long run. Studies from the field suggest that about two thirds to three quarters of all PVC membrane breakdown happens because of plasticizer loss over years of use, so keeping additives stable becomes a big deal for manufacturers. To fight against UV damage, companies often apply special stabilizers and reflective coatings on their products. These treatments protect the material during temperature changes and extended periods in direct sunlight, something that matters a lot for outdoor applications where membranes face constant weather exposure.

Average Lifespan of PVC Roofing Membranes: What to Expect

Good quality PVC roofing can stick around for about 20 to 30 years on average, though some top tier products actually go beyond 30 years if they're installed correctly and kept up with regular maintenance. Basic membrane types tend to start showing signs of wear after just 15 or so years, but newer advanced options with extra reinforcement layers and better stabilizer technology last much longer. The numbers tell an interesting story too. Industry reports indicate that around 7 out of 10 early failures happen because of installation issues rather than problems with the materials themselves. This really highlights why getting professional help matters so much when it comes to making sure these roofs perform as intended over their lifespan.

Factors That Influence Service Life: Installation, Maintenance, and Design

Three key factors disproportionately affect longevity:

- Installation precision: Heat-welded seams must achieve full fusion (3.5 lbs/inch peel strength) to prevent water ingress.

- Maintenance frequency: Annual inspections reduce leak risks by 40% (Ponemon 2023).

- System design: Slope, drainage, and penetrations influence stress distribution. High-traffic areas require protective walkway pads to minimize abrasion.

Recoating every 8–12 years restores UV protection and flexibility, significantly extending service life.

Environmental Resistance: How UV Exposure and Weather Impact PVC Membrane

UV Radiation and Photodegradation: Effects on PVC Membrane Integrity

UV radiation accelerates PVC degradation through photochemical breakdown of polymer chains. Untreated PVC can lose 35–40% of its tensile strength after five years of sun exposure, with surface cracking occurring 2.3 times faster in high-UV regions. Modern solutions mitigate this via:

- Reflective pigments deflecting 92% of UV rays

- UV absorbers converting radiation into harmless heat

- Antioxidants preventing free radical chain scission

Thermal Cycling, Humidity, and Temperature Extremes in Real-World Conditions

Daily temperature fluctuations cause PVC membranes to expand and contract by up to 0.25% per 18°F change. Over a decade, this equates to cumulative stress comparable to more than 4,500 mechanical load cycles. In humid coastal environments, plasticizer migration occurs 27% faster than in arid climates, necessitating enhanced stabilization for durable water resistance.

Artificial Weathering Studies and Predictive Aging Models

Standardized testing per ASTM G154 and ISO 4892-3 evaluates PVC performance under accelerated conditions:

| Test Parameter | Simulation Equivalent | Performance Threshold |

|---|---|---|

| 3,000 hrs UV exposure | 15 years Arizona sun | 5% τ in elongation at break |

| 500 freeze-thaw cycles | 20-year Midwest winter | Zero visible surface checking |

| 95% RH + 140°F | Tropical monsoon conditions | 0.02% mass loss |

These models support lifespan predictions of 25–30 years for membranes retaining 80% initial flexibility.

Protective Additives and Stabilizers That Enhance Environmental Resistance

Top-tier formulations incorporate:

- Hindered amine light stabilizers (HALS): Regenerate antioxidants, doubling UV protection duration

- Nano-titanium dioxide: Reflects 97% of UV-A/B while preserving translucency

- Hybrid plasticizers: Reduce leaching by 44% in wet environments versus traditional DINP

Systems combining these technologies exhibit less than 10% color shift after 10,000 kJ/m² UV exposure—seven times better than standard PVC.

Mechanical Strength and Structural Performance of PVC Membranes

Tensile Strength and Puncture Resistance in Heavy-Duty Applications

Oriented PVC formulations reach Minimum Required Strength (MRS) values of 40–50 MPa—nearly double standard grades—enabling robust resistance to punctures from hail, debris, and industrial foot traffic. With proper maintenance, optimized membranes retain up to 90% of their original puncture resistance over two decades.

Wind Uplift Resistance and Dynamic Load Handling

Flexibility and seam integrity are central to wind performance. Independently tested systems withstand pressures exceeding 2,865 Pa (per ASTM D6631), equivalent to 160 mph winds. The membrane’s ability to flex without cracking under cyclic loading is preserved through effective plasticizer retention, which prevents embrittlement over time.

Long-Term Watertightness and Waterproofing Reliability

PVC membranes maintain watertight integrity for 25–35 years, outperforming many thermoplastic alternatives. This reliability arises from:

- Consistent thickness (±0.02 mm tolerance), eliminating weak spots

- Extremely low water absorption (≤0.0012% at 23°C)

- Self-sealing behavior during thermal expansion due to thermoplasticity

Performance Under Foot Traffic and Mechanical Stress

While suitable for occasional foot traffic, sustained use demands protective walkways. Impact tests show 20 kJ/m² resistance at -20°C, declining only 15% after 10,000 load cycles. Advanced versions with reinforced polyester layers reduce surface deformation by 78% compared to non-reinforced types, as confirmed in biaxial stress studies.

Coating Stability and Plasticizer Retention in PVC Membranes

Role of Topcoats in UV and Chemical Protection

Engineered topcoats—typically acrylic or fluoropolymer-based—shield PVC membranes from UV radiation, ozone, and airborne pollutants. High-performance variants reduce UV transmission by 92–97% relative to uncoated PVC, dramatically slowing photochemical degradation (MDPI 2022). Chemically optimized coatings also demonstrate less than 5% weight loss after 1,000 hours in pH 3–11 environments.

Progressive Coating Wear and Substrate Exposure Risks

Coatings gradually erode due to abrasion, thermal cycling, and environmental stress. Field measurements indicate annual thickness losses of 0.5–2.0 microns depending on climate severity. At 50% coating loss, substrate exposure leads to:

- 300–800% increase in permeability

- 40–70% rise in plasticizer migration

- 15–20 Shore A unit gain in surface hardness

Early detection via infrared inspections allows intervention before functional decline occurs.

Do Plasticizers Leach Over Time? Impact on Flexibility and Cracking

Plasticizer retention is the most critical factor in maintaining long-term flexibility. Accelerated aging reveals 18–22% plasticizer loss after ten simulated years, resulting in:

- 30–50% reduction in cold bend performance (-20°C)

- Tripled crack propagation speed

- 25–35% loss in tensile strength

A 2024 polymer science study found crosslinked polymer networks enabled stabilized formulations to retain 94% of initial plasticizers after 15 simulated years. Proper seam welding and intact topcoats limit annual leaching rates to under 0.8% in well-executed installations.

Seam Integrity and Long-Term Joint Performance in PVC Roofing

Heat-Welded Seams: Strength, Seal Quality, and Durability

When heat welding creates seams, it actually forms bonds at the molecular level that are just as strong as the base material itself. Industrial tests show these welded connections can handle tensile forces exceeding 350 pounds per square inch. The real advantage here is that there are no weak spots where adhesives might fail. Most importantly, properly welded joints keep about 95% of their waterproof qualities even after standing up to harsh weather for over fifteen years. Getting those weld widths right matters a lot too. We're talking about keeping them consistently between 1.5 and 2 inches wide throughout the project. Even tiny mistakes matter - something like a 0.1 inch variation in width could cut the lifespan down by nearly a third when exposed to extreme temperature swings and heavy rainfall cycles.

Common Failure Modes: Thermal Cycling, Stress, and Poor Workmanship

Despite technological advances, three issues drive 78% of seam failures:

- Thermal stress: Daily swings ≥40°F induce 0.4% linear expansion/contraction per 100°F, straining welds

- Mechanical fatigue: Wind uplift forces over 90 psf can peel inadequately reinforced seams

- Installation errors: 23% of field seams fail ASTM D751 peel tests due to incorrect heat application or contamination

Data shows 75% of PVC roof leaks originate within 18“ of seams. Infrared thermography scans every 36 months detect 89% of developing issues early. During hurricane-force wind testing in 2022, no welded seams failed up to 150 mph—provided installation met manufacturer specifications.

FAQ Section

What factors contribute to the durability of PVC membrane systems?

The durability of PVC membranes is influenced by their environmental resistance, mechanical strength, and chemical stability. Key performance metrics include tensile strength, puncture resistance, and plasticizer retention.

What is the average lifespan of PVC roofing membranes?

On average, good quality PVC roofing lasts 20 to 30 years, with some top-tier products exceeding 30 years. Proper installation and maintenance significantly extend their lifespan.

How do environmental factors affect PVC membranes?

Environmental conditions such as UV radiation, temperature fluctuations, and humidity play a major role in PVC degradation. Modern technologies like reflective pigments and UV absorbers help mitigate these effects.

How is the integrity of PVC membrane seams maintained?

Heat welding forms strong, durable seams that maintain waterproof qualities over time. Proper installation techniques, including consistent weld widths, are crucial for longevity.

Table of Contents

- What Determines the Durability of PVC Membrane Systems?

- Environmental Resistance: How UV Exposure and Weather Impact PVC Membrane

- Mechanical Strength and Structural Performance of PVC Membranes

- Coating Stability and Plasticizer Retention in PVC Membranes

- Seam Integrity and Long-Term Joint Performance in PVC Roofing

- FAQ Section